Did you know that barite, a dense mineral composed of barium sulfate, is crucial for oil drilling, medical imaging, and industrial applications? Discover how this versatile mineral is mined, processed, and traded worldwide.

Table of Contents

What is Barite?

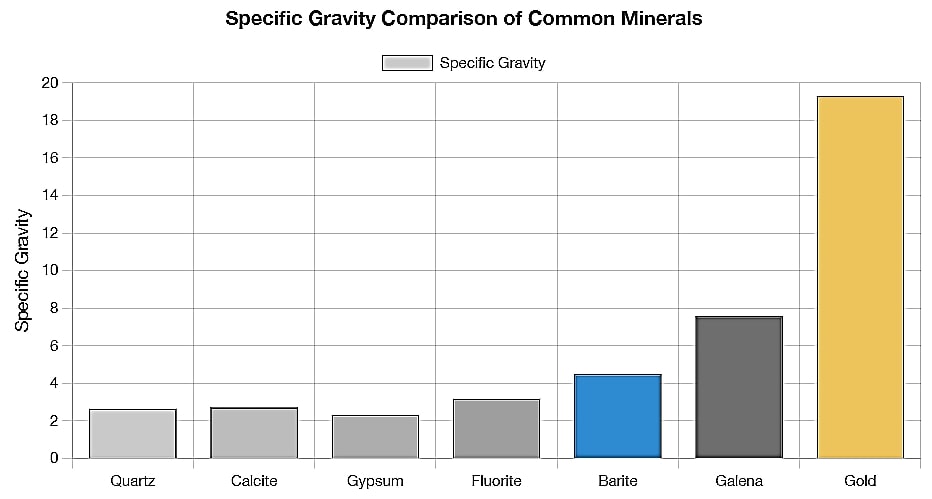

Barite (also known as baryte) is a mineral consisting of barium sulfate (BaSO₄). It is the primary ore of barium and a common mineral that occurs in a variety of depositional environments. It is particularly notable for its high specific gravity, which makes it valuable for various industrial applications.

Key Fact: Barite derives its name from the Greek word barys, which means “heavy,” reflecting its remarkably high specific gravity of 4.3 to 5.0.

Chemical Composition and Structure

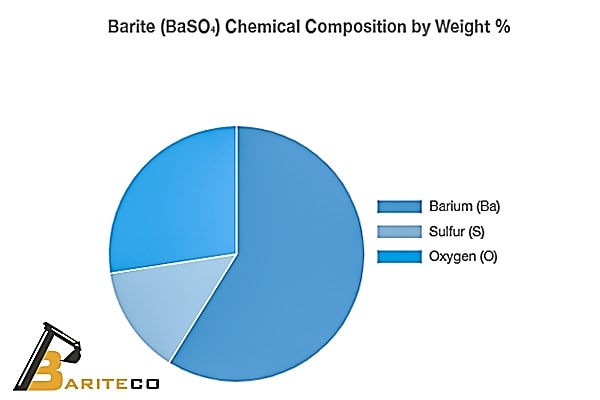

Barite is composed primarily of barium sulfate (BaSO₄), an inorganic compound that forms as an orthorhombic crystal system. The mineral typically contains 58.84% barium oxide (BaO) and 41.16% sulfur trioxide (SO₃), although natural samples often contain impurities that can modify these percentages.

Elemental Composition

Crystal Structure

Barite crystallizes in the orthorhombic system, typically forming tabular crystals. The crystal structure features layers of barium ions alternating with layers of sulfate ions, resulting in its characteristic high density. Some key crystallographic parameters include:

| Property | Value |

| Crystal System | Orthorhombic |

| Unit Cell Dimensions | a = 8.87 Å, b = 5.45 Å, c = 7.14 Å |

| Space Group | Pnma |

| Z (formula units per cell) | 4 |

Common Impurities

Natural barite often contains various impurities that can affect its color, density, and other properties:

- Strontium (Sr): can partially substitute for barium

- Calcium (Ca): common impurity in sedimentary barite

- Lead (Pb): can be present in hydrothermal deposits

- Radium (Ra): trace amounts may be present due to chemical similarity to barium

- Iron (Fe): responsible for yellowish or reddish tints

Geological Occurrence

Barite is found worldwide in various geological settings. Its formation is typically associated with hydrothermal activity, but it can also form through other processes:

| Type of Deposit | Formation Process | Notable Locations |

| Hydrothermal Vein | Precipitation from hot, mineral-rich fluids in rock fractures | Germany (Harz Mountains), UK (Cornwall), USA (Nevada) |

| Bedded Deposits | Precipitation in marine sedimentary environments | USA (Nevada, Georgia), China (Guizhou), India (Mangampet) |

| Residual Deposits | Concentration through weathering of barite-bearing rocks | USA (Missouri), Mexico |

| Cavity-Fill Deposits | Precipitation in limestone cavities | Missouri (USA), Morocco |

Did you know? The world’s largest barite deposit is located at Mangampet in Andhra Pradesh, India, with estimated reserves of over 70 million tonnes.

Physical Properties of Barite

Barite is known for its distinctive physical properties, particularly its high specific gravity, which makes it valuable for various applications. It occurs in a range of colors and forms depending on the geological conditions of formation.

Key Physical Properties

| Property | Value/Description |

| Chemical Formula | BaSO₄ |

| Color | Colorless, white, yellow, blue, brown, gray |

| Streak | White |

| Luster | Vitreous to pearly |

| Transparency | Transparent to opaque |

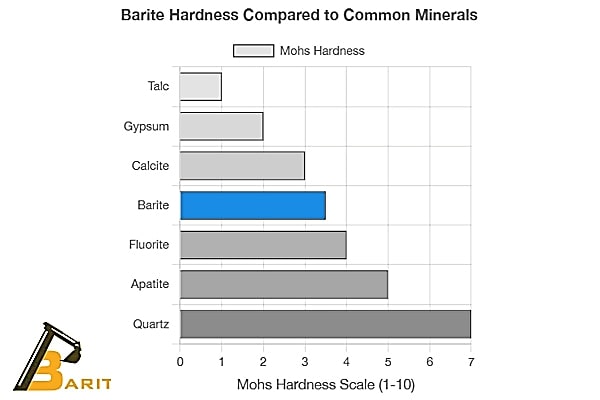

| Mohs Hardness | 3.0 – 3.5 |

| Specific Gravity | 4.3 – 5.0 |

| Cleavage | Perfect in one direction, good in another |

| Fracture | Uneven to conchoidal |

| Melting Point | 1,580°C (2,876°F) |

| Solubility | Practically insoluble in water and acids |

Varieties and Forms

Barite occurs in several different forms and habits, depending on its formation conditions:

| Form | Description | Typical Formation Environment |

| Tabular Crystals | Flat, plate-like crystals with well-defined faces | Hydrothermal veins |

| Bladed Aggregates | Clusters of blade-shaped crystals | Hydrothermal deposits |

| Desert Rose | Rose-like aggregate of barite crystals with sand inclusions | Arid environments with evaporation |

| Nodular | Rounded masses within sedimentary rocks | Marine sedimentary environments |

| Massive | Dense, compact masses without visible crystals | Various environments |

Geological Occurrence

Barite is found worldwide in various geological settings. Its formation is typically associated with hydrothermal activity, but it can also form through other processes:

| Type of Deposit | Formation Process | Notable Locations |

| Hydrothermal Vein | Precipitation from hot, mineral-rich fluids in rock fractures | Germany (Harz Mountains), UK (Cornwall), USA (Nevada) |

| Bedded Deposits | Precipitation in marine sedimentary environments | USA (Nevada, Georgia), China (Guizhou), India (Mangampet) |

| Residual Deposits | Concentration through weathering of barite-bearing rocks | USA (Missouri), Mexico |

| Cavity-Fill Deposits | Precipitation in limestone cavities | Missouri (USA), Morocco |

Did you know? The world’s largest barite deposit is located at Mangampet in Andhra Pradesh, India, with estimated reserves of over 70 million tonnes.

Uses of Barite

Due to its high specific gravity and chemical inertness, barite is widely used across numerous industries. Here are the primary applications of barite in modern industry:

Industrial Applications

| ndustry | Application | Usage % |

| Oil & Gas | Drilling fluid weighting agent | 80% |

| Medical | Barium meal for X-ray diagnostics | 5% |

| Paints & Coatings | Pigment extender, filler | 4% |

| Radiation Shielding | Concrete additive, protective barriers | 3% |

| Plastics | Filler, sound dampening | 3% |

| Rubber & Glass | Manufacturing additive | 2% |

| Other | Paper coating, friction products | 3% |

Drilling Industry

The most significant use of barite is in drilling fluids or “mud” used in oil and gas exploration:

- Weight Agent: Added to drilling fluid to increase its density, controlling formation pressure and preventing blowouts

- Specifications: Must meet API (American Petroleum Institute) standards for specific gravity (min. 4.2) and chemical composition

- Advantages: Chemically inert, non-magnetic, relatively soft (won’t damage drilling equipment), and insoluble

Medical Applications

Barite is processed to create barium compounds used in medical diagnostics:

- Barium Sulfate Suspension: Used as a contrast medium in X-ray examinations of the digestive tract

- Barium Enema: For examining the lower intestinal tract

- Safety: Unlike soluble barium compounds which are toxic, BaSO₄ is insoluble and passes through the body without being absorbed

Global Production

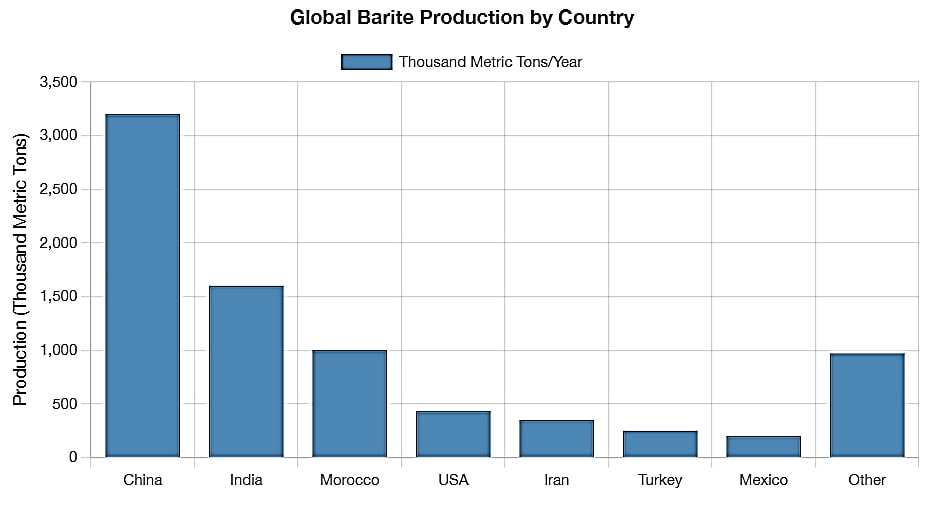

The global barite mining industry is concentrated in several key countries:

Market Value and Trends

The global barite market is closely tied to the oil and gas industry:

- Market Size: Valued at approximately $2.5 billion globally

- Growth Drivers: Increasing deep-water drilling activities, expansion of oil and gas exploration

- Price Factors: Grade (SG), processing level, location proximity to markets

- Future Trends: Growing demand in radiation shielding applications and environmentally friendly drilling practices

Geological Occurrence

Barite is found worldwide in various geological settings. Its formation is typically associated with hydrothermal activity, but it can also form through other processes:

| Type of Deposit | Formation Process | Notable Locations |

| Hydrothermal Vein | Precipitation from hot, mineral-rich fluids in rock fractures | Germany (Harz Mountains), UK (Cornwall), USA (Nevada) |

| Bedded Deposits | Precipitation in marine sedimentary environments | USA (Nevada, Georgia), China (Guizhou), India (Mangampet) |

| Residual Deposits | Concentration through weathering of barite-bearing rocks | USA (Missouri), Mexico |

| Cavity-Fill Deposits | Precipitation in limestone cavities | Missouri (USA), Morocco |

Did you know? The world’s largest barite deposit is located at Mangampet in Andhra Pradesh, India, with estimated reserves of over 70 million tonnes.

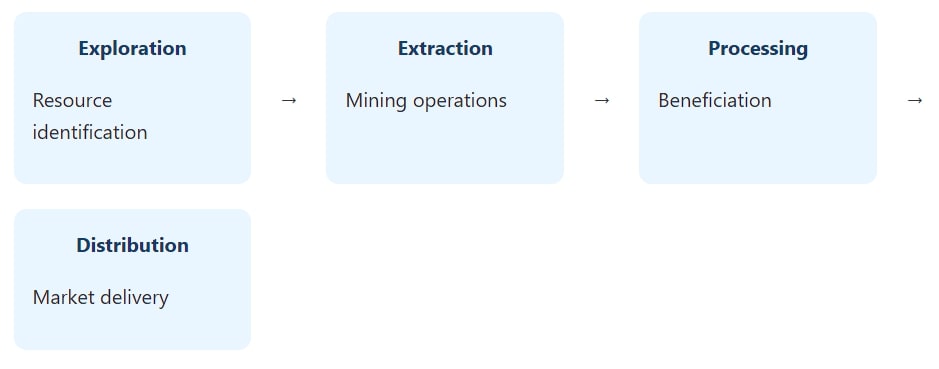

The Barite Mining Process

The extraction of barite from the earth follows a systematic process that has evolved with technological advancements while remaining fundamentally focused on efficiently separating this valuable mineral from surrounding materials. Modern barite mining combines geological expertise, engineering principles, and environmental management to optimize recovery while minimizing ecological impacts.

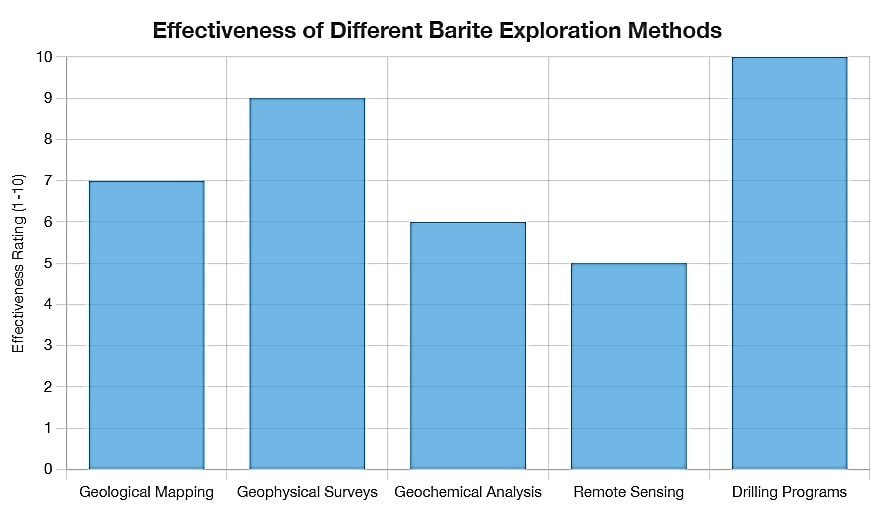

Exploration and Prospecting

Barite exploration begins with comprehensive geological surveys to identify potential deposits with economically viable concentrations. Unlike the prospecting methods for precious metals, barite exploration relies heavily on understanding sedimentary environments and hydrothermal systems where this mineral typically forms.

Modern exploration campaigns employ multiple complementary techniques to maximize discovery potential while minimizing costs. The integration of traditional field methods with advanced remote sensing and geophysical techniques has dramatically improved exploration success rates.

Remote Sensing and Preliminary Assessment

Initial exploration typically employs satellite imagery and aerial surveys to identify promising geological formations. These remote sensing techniques can detect structural features, lithological variations, and alteration patterns associated with barite mineralization. Hyperspectral imaging has proven particularly valuable for identifying spectral signatures characteristic of barite-bearing rocks, even when not exposed at the surface.

Ground-Based Exploration

Field geologists conduct detailed mapping of potential deposit areas, collecting rock samples for laboratory analysis. The distinctive high specific gravity of barite makes field identification easier than many other minerals a simple “heft test” can provide initial indications of barite content. Stream sediment sampling often proves effective in regions with active drainage systems, as the high density of barite causes it to concentrate in stream beds.

Geophysical Surveys

Given barite’s high density compared to most host rocks, gravity surveys represent a particularly effective geophysical technique for detecting potential deposits. Modern gravimeters can detect subtle variations in the gravitational field caused by subsurface barite concentrations. Resistivity surveys and induced polarization techniques complement gravity data by providing information about rock properties that may indicate favorable host environments.

Exploration Drilling

Once promising targets have been identified through preliminary methods, exploration drilling provides definitive evidence of barite mineralization. Core samples retrieved from strategic locations undergo comprehensive analysis to determine:

- Barite content and grade (% BaSO₄)

- Deposit dimensions and geometry

- Presence of impurities that might affect processing

- Structural features influencing mining methods

Resource Estimation

Data from exploration activities culminate in resource estimation a critical step that determines whether a deposit warrants commercial development. Geologists classify resources according to confidence levels (measured, indicated, and inferred) based on sampling density and geological understanding. Advanced geostatistical techniques, including kriging and 3D modeling, help visualize the deposit and quantify recoverable reserves with associated confidence intervals.

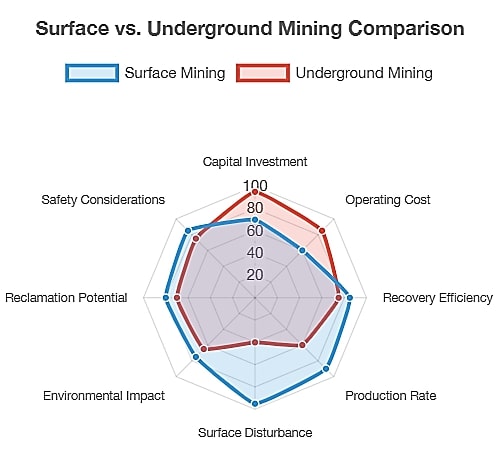

Extraction Methods

The approach to extracting barite from the earth depends significantly on the deposit type, depth, size, and local geological conditions. Mining engineers select methods that optimize recovery while considering economic, environmental, and safety factors. Modern barite extraction employs both surface and underground techniques, with the choice driven by deposit characteristics and site-specific constraints.

Before full-scale mining begins, extensive planning and preparation activities take place, including:

- Developing detailed mine plans and production schedules

- Securing necessary permits and regulatory approvals

- Establishing infrastructure (roads, power, water management systems)

- Implementing environmental monitoring networks

- Training personnel on operational and safety procedures

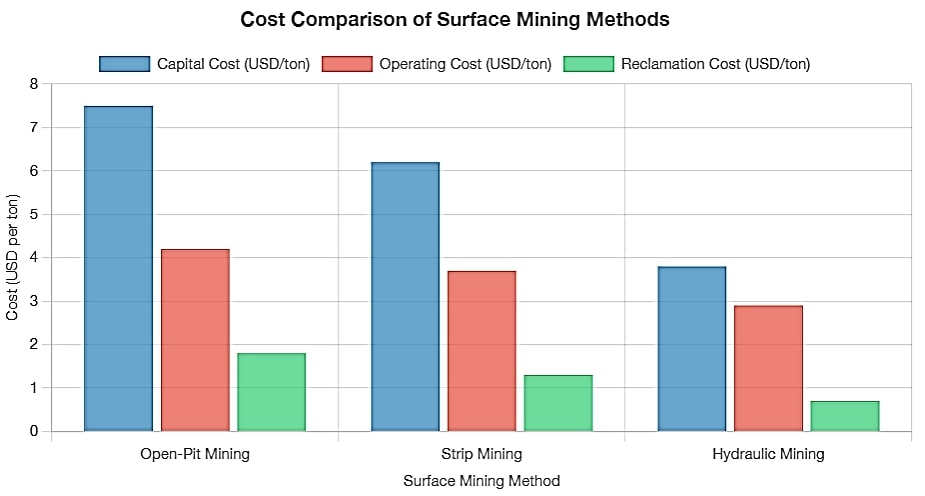

The mining method selection process weighs numerous factors, including capital investment requirements, operating costs, recovery efficiency, environmental impact, and site rehabilitation potential. The geological characteristics of the deposit particularly its depth, orientation, and relationship to surrounding rock units often prove decisive in this selection process.

Surface Mining

Surface mining techniques dominate barite extraction globally, accounting for approximately 70% of production. These methods prove particularly suitable for shallow deposits (typically less than 200 meters deep) and larger mineral bodies where the economics favor removing overburden to access the valuable mineral.

Open-Pit Mining

For substantial barite deposits with relatively uniform mineralization, open-pit operations offer efficient extraction capabilities. This method creates a large excavation that expands progressively deeper and wider as mining advances. The process follows systematic steps:

- Vegetation and Topsoil Removal: Carefully salvaged for later reclamation

- Overburden Removal: Drilling, blasting, and excavation of waste rock overlying the ore body

- Ore Extraction: Selective mining of barite-bearing material, often requiring controlled blasting to minimize dilution

- Haulage: Transportation of ore to processing facilities and waste to disposal areas

- Reclamation: Progressive rehabilitation of mined-out areas when possible

Modern open-pit barite operations employ sophisticated equipment fleets, including hydraulic excavators, wheel loaders, articulated or rigid-frame haul trucks, and various support equipment. Computer-aided design and fleet management systems optimize pit development and equipment utilization, significantly enhancing operational efficiency.

Strip Mining

In regions where barite deposits occur as relatively flat, shallow beds, strip mining offers advantages through progressive extraction and reclamation. This approach involves:

- Mining in sequential strips or blocks

- Placing overburden from active strips into previously mined areas

- Maintaining a smaller active mining footprint

- Enabling faster rehabilitation of disturbed areas

Strip mining proves particularly advantageous in agricultural regions, as progressive reclamation allows faster return of land to productive use. The method typically achieves lower ore dilution than open-pit approaches, potentially reducing processing requirements.

Hydraulic Mining

For unconsolidated or weathered barite deposits, particularly residual concentrations developed through weathering of primary deposits, hydraulic mining techniques may prove effective. High-pressure water jets dislodge the barite-bearing material, with the resulting slurry collected in sumps for pumping to processing facilities. While less common than conventional methods, this approach can provide cost advantages for suitable deposits while eliminating blasting requirements.

Surface mining operations increasingly incorporate advanced technologies to improve efficiency and reduce environmental impact. GPS-guided equipment, drone surveys for volumetric measurement, and real-time grade control systems represent just a few innovations transforming modern barite extraction.

Underground Mining

When barite deposits extend deep beneath the surface or occur in conditions unsuitable for open-pit mining, underground extraction becomes necessary. These methods access the mineral while leaving much of the overlying rock intact, reducing surface disturbance but often increasing operational complexity and cost. Underground approaches prove particularly valuable for high-grade veins, deep bedded deposits, and locations with surface constraints.

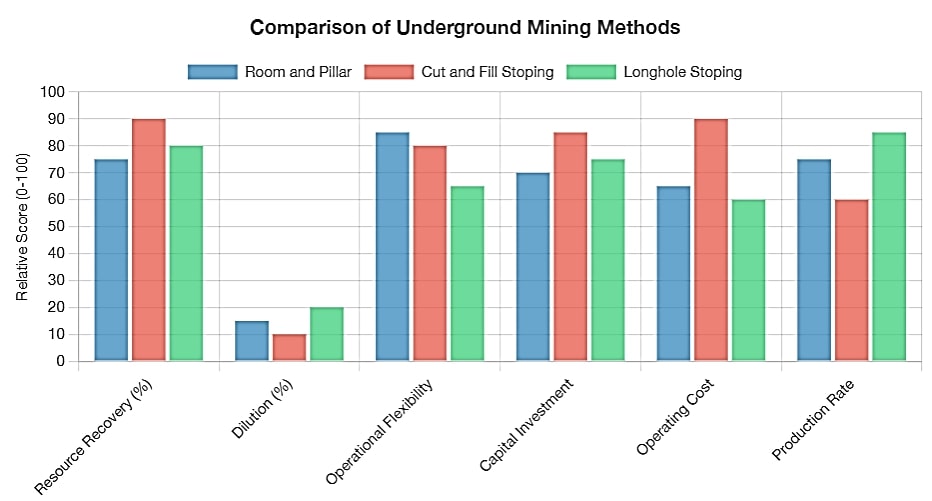

Room and Pillar Mining

For relatively flat-lying, bedded barite deposits with competent roof conditions, room and pillar mining offers an effective extraction strategy. This method:

- Creates a network of “rooms” (open spaces) while leaving “pillars” of ore to support the overlying rock

- Progresses in a regular pattern, with pillar dimensions engineered based on depth, ground conditions, and production requirements

- May recover pillar material during final retreat mining, though this requires careful ground control

- Typically achieves 60-80% recovery of the mineral resource

Room and pillar operations utilize specialized equipment including low-profile loaders, continuous miners or drill-and-blast methods, and shuttle cars or conveyor systems for ore transport. This approach offers flexibility to adapt to variations in ore quality and geological conditions.

Cut and Fill Stoping

For steeper, irregular barite veins, particularly those requiring greater selectivity, cut and fill methods provide advantages. This approach:

- Extracts ore in horizontal slices, working upward from the bottom of a stope

- Backfills each completed slice with waste material to create a working platform for mining the next slice

- Achieves high recovery rates with minimal dilution

- Provides excellent ground control through systematic backfilling

Modern cut and fill operations often utilize cemented backfill, incorporating tailings from the mineral processing plant with cement to create a stable fill material. This practice not only enhances mine stability but also reduces surface tailings disposal requirements.

Longhole Stoping

For larger, more uniform barite deposits with good rock quality, longhole stoping offers higher productivity and lower direct operating costs. This method:

- Develops access drifts (tunnels) above and below blocks of ore

- Drills long blastholes between levels

- Blasts sections of the ore block, allowing broken material to fall to the lower level for collection

- May employ backfilling of mined-out stopes or leave them empty depending on ground conditions

Longhole stoping typically achieves lower direct mining costs but may experience higher dilution compared to more selective methods. Remote-controlled and automated loading equipment increasingly feature in these operations, enhancing safety by removing operators from potentially hazardous areas.

Underground barite mining operations face unique ventilation challenges. Sufficient airflow must maintain a safe working environment while managing heat, humidity, dust, and potential radon emissions. Modern mines employ sophisticated ventilation-on-demand systems that automatically adjust airflow based on equipment locations and operational requirements.

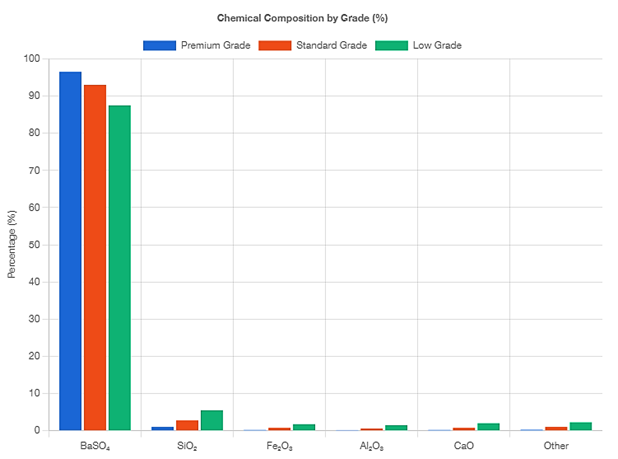

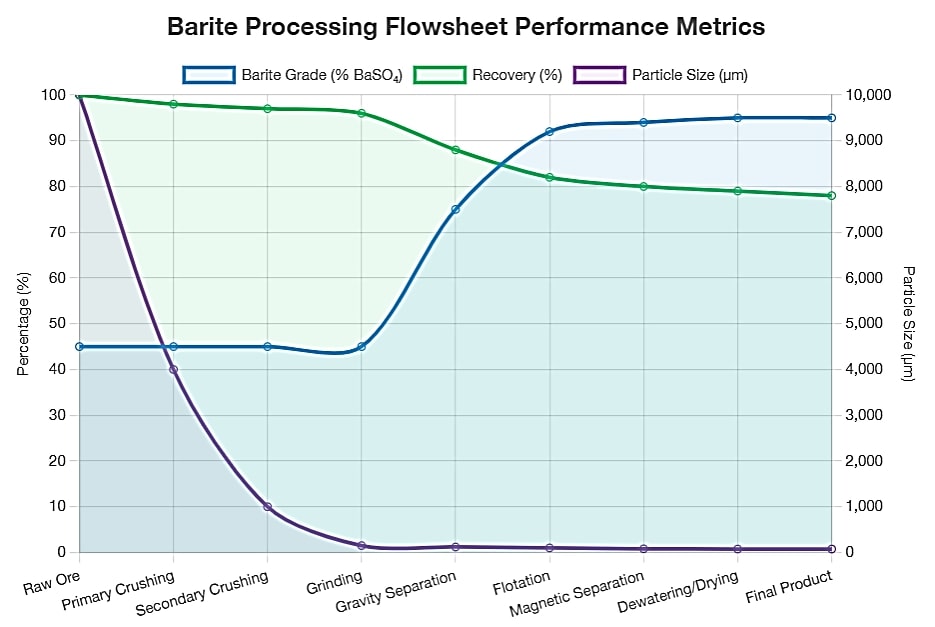

Processing and Beneficiation

Raw barite ore extracted from the earth typically contains various impurities and associated minerals that must be removed to create marketable products meeting industry specifications. The beneficiation process transforms this heterogeneous material into refined products with controlled properties, employing both mechanical and physicochemical methods tailored to the specific characteristics of the ore.

Primary Crushing and Screening

The beneficiation journey begins with size reduction through primary crushing, typically employing jaw or gyratory crushers capable of handling large rocks from the mining operation. This initial crushing reduces material to manageable sizes (generally 100-150mm) for subsequent processing steps. Primary screening removes oversized material for recrushing while allowing properly sized material to advance.

Secondary and Tertiary Crushing

Further size reduction occurs through secondary and sometimes tertiary crushing circuits, often utilizing cone crushers or impact crushers. These stages progressively reduce particle size while improving mineral liberation—separating barite from attached waste minerals. Closed-circuit operation with classification screens ensures only appropriately sized material proceeds to grinding operations.

Grinding

Fine grinding achieves final liberation of barite particles and prepares material for concentration processes. Depending on ore characteristics and required product specifications, grinding may employ:

- Ball mills: steel or ceramic balls in rotating drums for general grinding applications

- Rod mills: steel rods providing more selective grinding action

- Vertical mills: increasingly used for energy-efficient fine grinding

Grinding circuits typically operate in closed loop with classification systems such as hydrocyclones or mechanical classifiers, ensuring only material ground to target size advances to concentration stages.

Gravity Concentration

The significant density difference between barite (4.3-5.0 g/cm³) and most gangue minerals (2.5-3.0 g/cm³) enables effective gravity-based separation. Depending on feed characteristics and required specifications, operations may employ:

- Jigs: pulsating water flow separates particles based on density differences

- Spirals: helical channels where centrifugal forces and gravity separate minerals

- Shaking tables: inclined vibrating decks where water flow and vibration create density separation

- Heavy media separation: using a fluid with intermediate density to separate light and heavy materials

Many barite operations achieve acceptable product quality using gravity concentration alone, particularly for drilling-grade applications where some impurities remain acceptable.

Flotation

For higher-purity requirements or complex ores where gravity methods prove insufficient, flotation offers enhanced separation capabilities. This process:

- Uses specialized reagents to modify mineral surface properties

- Creates hydrophobic conditions on desired minerals

- Introduces air bubbles that attach to hydrophobic particles

- Recovers mineral-laden bubbles as a concentrate

Flotation proves particularly valuable for separating barite from sulfide minerals, fluorite, celestite, and other minerals with similar specific gravity. The process often employs collectors such as fatty acids or petroleum sulfonates, modifiers to control pH and surface conditions, and frothers to stabilize bubbles.

Magnetic Separation and Leaching

For premium-grade barite applications, particularly in paint, filler, and pharmaceutical markets, additional purification steps may include:

- Magnetic separation: removing iron-bearing impurities using low or high-intensity magnetic separators

- Chemical leaching: dissolving soluble impurities while leaving insoluble barite intact

- Bleaching: chemical treatments to improve whiteness for color-sensitive applications

Dewatering and Drying

The final stages of processing typically involve removing moisture to meet product specifications and reduce transportation costs. Depending on the operation and product requirements, this may involve:

- Thickening: using gravity settlers or mechanical thickeners to increase solids content

- Filtration: mechanical methods such as pressure filters, vacuum filters, or centrifuges

- Thermal drying: rotary dryers, fluid bed dryers, or flash dryers for final moisture control

Product Classification and Packaging

Finished barite undergoes final sizing to meet customer specifications, typically using air classifiers or fine screens. Modern processing facilities may produce multiple product grades from a single ore source, maximizing resource utilization and market flexibility. Packaging operations prepare material for transport, using bulk bags, drums, or bulk shipment depending on customer requirements and logistics considerations.

Quality control represents a critical aspect of barite processing, with regular testing throughout the production chain to ensure consistent product properties. Key quality parameters include specific gravity, chemical composition (BaSO₄ content), particle size distribution, brightness (for white barite), and moisture content all tailored to end-use requirements.

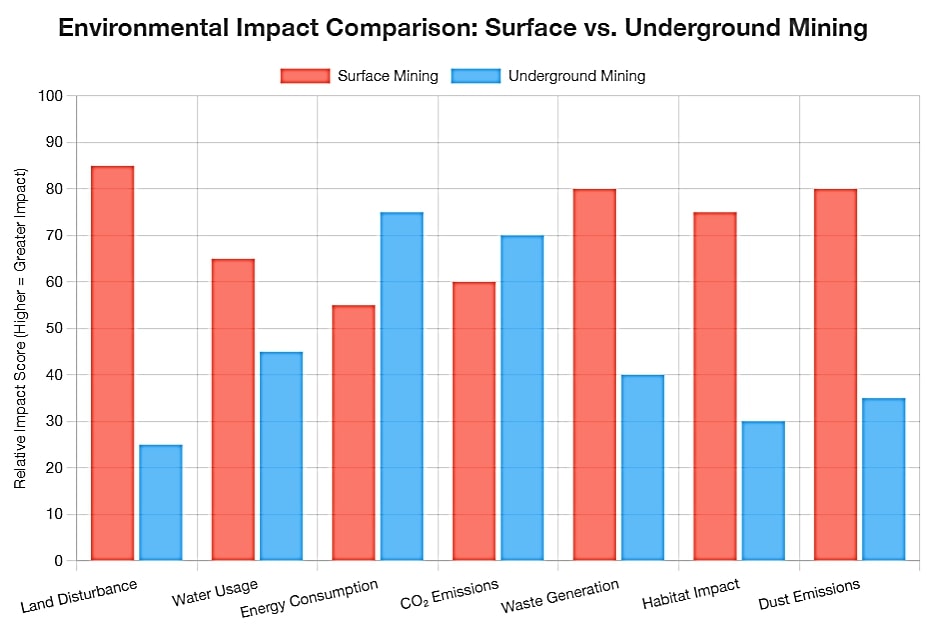

Environmental Impact of Barite Mining

Like all extractive industries, barite mining alters the natural environment, creating both direct and indirect impacts that require careful management. The environmental footprint varies significantly based on mining method, processing technology, site-specific conditions, and regulatory frameworks. Modern operations increasingly emphasize impact minimization and sustainability throughout the mine lifecycle.

Land Degradation and Habitat Loss

Surface mining methods, particularly open-pit operations, create the most visible environmental changes through land disturbance. These impacts include:

- Vegetation removal and topsoil disturbance

- Alteration of landscape contours and drainage patterns

- Habitat fragmentation and potential loss of biodiversity

- Visual impacts on scenic landscapes

- Potential for soil erosion and sedimentation in waterways

The magnitude of these impacts correlates directly with the operation’s footprint and intensity. Large open-pit mines may disturb hundreds of hectares, while smaller underground operations might affect relatively limited surface areas for access infrastructure and processing facilities.

Progressive reclamation practices have evolved significantly in modern mining, with many operations implementing concurrent rehabilitation that restores mined areas while extraction continues elsewhere. Successful reclamation can establish productive post-mining land uses, including agriculture, forestry, wildlife habitat, or recreational areas, though complete restoration of original ecosystems often proves challenging.

Water and Air Pollution

Water quality protection represents a critical environmental concern in barite mining regions. Potential water impacts include:

- Sediment loading from disturbed areas during rainfall events

- Potential acid rock drainage if sulfide minerals occur with barite

- Process water containing suspended solids or reagent residues

- Altered hydrology affecting groundwater and surface water systems

Comprehensive water management systems in modern operations address these concerns through infrastructure such as diversion channels, sedimentation ponds, treatment facilities, and water recycling systems. Regular monitoring of both surface and groundwater quality provides early detection of potential issues and verification of control measure effectiveness.

Air quality considerations in barite mining operations primarily involve particulate emissions (dust) generated during blasting, excavation, crushing, and transport activities. Additional air quality concerns may include:

- Equipment emissions from diesel-powered mining machinery

- Processing emissions, particularly from drying operations

- Wind erosion from exposed surfaces and stockpiles

Control strategies typically include dust suppression systems, enclosed processing facilities, surfaced haul roads, vegetative buffers, and equipment maintenance programs to minimize emissions.

Mitigation Strategies

Modern barite mining operations implement comprehensive environmental management systems addressing all phases from exploration through closure. Effective mitigation approaches include:

Planning and Design Phase:

- Conducting thorough environmental baseline studies before development

- Incorporating environmental considerations into mine design

- Developing detailed environmental management plans

- Engaging with communities and stakeholders during planning

Operational Phase:

- Implementing best available technologies for pollution control

- Practicing progressive reclamation concurrent with mining

- Minimizing waste generation and maximizing resource efficiency

- Conducting regular environmental monitoring and reporting

- Training personnel on environmental responsibilities

Closure and Post-Mining Phase:

- Comprehensive site rehabilitation to stable, productive condition

- Long-term monitoring programs to verify closure success

- Financial provisions for post-closure management requirements

The evolution of regulatory frameworks globally has significantly improved environmental performance in the mining sector. Leading barite producers increasingly adopt standards exceeding regulatory minimums, recognizing that environmental stewardship represents both an ethical imperative and a business advantage in markets valuing sustainable production.

Economic Aspects of Barite Mining

The economics of barite mining reflect complex interactions between geological factors, technological capabilities, market dynamics, and regulatory frameworks. Understanding these economic dimensions proves essential for evaluating project viability, investment decisions, and long-term industry trends.

Global Barite Market

The global barite market maintains close ties to energy sector dynamics, particularly oil and gas drilling activity, which drives approximately 80% of demand. This connection creates characteristic cyclical patterns, with barite consumption and prices following broader energy industry trends. Notable market features include:

Supply Factors:

- Concentrated production with 70% coming from five countries (China, India, Morocco, United States, and Iran)

- Varying production costs across regions due to differences in deposit characteristics, labor costs, and regulatory requirements

- Transportable reserves estimated at 740 million tonnes globally, providing multi-decade supply at current consumption rates

- Strategic stockpiling by some countries to ensure drilling material availability

Demand Factors:

- Drilling activity levels, particularly in offshore and deep formations requiring higher mud weights

- Growing industrial applications in radiation shielding, plastics, and specialty chemicals

- Regional demand variations based on oil and gas development intensity

- Quality specifications driving premium pricing for higher-grade material

Market Dynamics:

- Grade differentiation with API-grade (4.2 SG minimum) commanding premium pricing in drilling markets

- Significant transportation component in delivered pricing, creating regional supply advantages

- Increasing attention to consistent quality and reliable supply rather than lowest price alone

- Growing interest in barite recovery from drilling mud recycling to reduce environmental impacts

The barite market has experienced notable volatility, with prices fluctuating substantially during energy market expansions and contractions. Price ranges typically span $80-220 per tonne depending on grade, processing level, and market conditions, with premium industrial grades commanding the highest values.

Key Players in the Industry

The global barite mining industry features diverse participants ranging from multinational corporations to specialized regional producers:

1- Major Producers:

- Andhra Pradesh Mineral Development Corporation (India) – operators of the world’s largest barite mine at Mangampet

- Guizhou Saboman Mining Co. (China) – major producer from bedded deposits

- Halliburton and Baker Hughes (USA) – vertically integrated drilling service companies with barite mining operations

- M-I SWACO (Schlumberger) – global producer with mines in multiple countries

- Anglo Pacific Minerals (UK) – significant producer with operations in Morocco

2Industry Structure:

- Vertical integration common among larger players connecting mining operations with drilling fluid manufacturing

- Specialized regional producers focusing on specific market segments or grades

- Trading companies facilitating global distribution from production regions to consumption centers

- Increasing consolidation through mergers and acquisitions, particularly among mid-sized producers

The industry continues to evolve with changing market conditions, particularly as energy transition trends influence traditional demand patterns. Forward-looking companies increasingly diversify into non-drilling applications, develop enhanced recovery techniques, and emphasize sustainable production practices to create competitive advantages.

The Future of Barite Mining

The barite mining industry stands at a pivotal juncture, navigating both challenges and opportunities arising from energy transition trends, technological advancements, and evolving societal expectations. While traditional markets continue to drive demand, emerging applications and production innovations are reshaping the sector’s future trajectory.

Technological Advancements

Technological innovation across the mining value chain is transforming how barite deposits are discovered, extracted, and processed:

Exploration Technologies:

- Advanced geophysical techniques with improved resolution for detecting smaller or deeper deposits

- Machine learning algorithms analyzing exploration data to identify subtle mineralization patterns

- Drone-based remote sensing providing cost-effective preliminary surveys

- Portable XRF analyzers enabling rapid field assessment of barium content

Mining Innovations:

- Increasing automation of equipment, reducing operator exposure and improving efficiency

- Electrification of mining fleets to reduce emissions and operating costs

- Real-time grade control systems minimizing dilution and optimizing recovery

- Advanced ground control technologies improving safety in underground operations

Processing Advancements:

- Energy-efficient grinding technologies reducing power consumption

- Enhanced sensor-based sorting systems separating ore from waste before intensive processing

- Advanced flotation chemistry improving selectivity for complex ores

- Dry processing methods reducing water consumption in arid regions

Digital transformation stands as perhaps the most significant technological trend, with integrated systems connecting all aspects of the mining value chain. From digital twins of processing plants to predictive maintenance systems and real-time production optimization, these technologies enhance efficiency while reducing environmental footprints.

Sustainable Mining Practices

Sustainability has evolved from a peripheral consideration to a central business imperative in modern barite mining. Forward-looking operations increasingly embrace comprehensive approaches addressing environmental, social, and governance dimensions:

Environmental Sustainability:

- Transitioning to renewable energy sources for mining and processing operations

- Implementing water recycling systems to minimize fresh water consumption

- Developing closed-loop processing with zero discharge objectives

- Enhancing biodiversity outcomes through advanced ecological restoration techniques

- Measuring and managing carbon footprints across the supply chain

Social Sustainability:

- Deeper community engagement through participatory planning and benefit-sharing

- Enhanced local employment and skills development programs

- Respect for indigenous rights and cultural heritage

- Transparent reporting on social performance metrics

Economic Sustainability:

- Lifecycle planning from exploration through closure and post-mining land use

- Diversification of product applications to reduce market volatility effects

- Value-added processing to create higher-margin specialty products

- Integration of circular economy principles through waste recovery and reprocessing

The concept of “shared value” increasingly shapes industry leaders’ approach to sustainability, recognizing that creating economic value through methods that simultaneously address societal and environmental challenges represents the most sustainable business model for extractive industries in the 21st century.

Regulations and Standards

The regulatory framework governing barite mining has evolved significantly, reflecting growing societal expectations for environmental protection, workplace safety, and responsible resource development. These regulations, while varying across jurisdictions, share common objectives of ensuring sustainable development while enabling economic benefits from mineral extraction.

Environmental Regulations

Environmental oversight of barite mining operations typically encompasses multiple dimensions with jurisdiction-specific requirements:

Permitting Process:

- Environmental impact assessments evaluating potential effects before project approval

- Public consultation requirements ensuring stakeholder input

- Financial assurance mechanisms guaranteeing funds for reclamation

- Periodic permit renewal with compliance verification

Operational Compliance:

- Air emission standards for dust, exhaust, and processing emissions

- Water quality discharge limits protecting surface and groundwater resources

- Waste management requirements for overburden, tailings, and process residues

- Hazardous materials handling and storage protocols

- Noise and vibration restrictions, particularly near populated areas

Closure Requirements:

- Site rehabilitation standards ensuring long-term stability and ecological function

- Post-closure monitoring obligations verifying reclamation success

- Financial mechanisms guaranteeing funds for closure activities

Regulatory frameworks continue to evolve, with increasing emphasis on life-cycle assessment, cumulative impacts across multiple operations, and integration of climate change considerations into approval and operational requirements.

Safety Standards

Worker protection represents a critical regulatory dimension for barite mining operations, with comprehensive standards addressing various occupational hazards:

- Ground control requirements preventing rock falls and slope failures

- Ventilation standards ensuring adequate air quality in underground operations

- Equipment safety specifications and maintenance requirements

- Personal protective equipment standards appropriate to specific tasks

- Training certification requirements for specialized roles

- Emergency response protocols and evacuation procedures

- Reporting obligations for incidents and near-misses

Modern regulatory approaches increasingly emphasize management systems rather than prescriptive requirements alone, requiring operators to implement comprehensive safety programs with risk assessment, hazard identification, training, and continuous improvement components.

Product Quality Standards

Barite products, particularly those used in oil and gas drilling, must meet industry-established specifications:

- American Petroleum Institute (API) Specification 13A establishing drilling-grade barite requirements

- OCMA (Oil Companies Materials Association) standards for specific gravity and particle size

- FEPA (Federation of European Producers of Abrasives) standards for industrial applications

- Pharmaceutical-grade requirements under various pharmacopeia for medical applications

These standards ensure consistent performance across applications while providing reference points for quality control throughout production and distribution chains.

International Standards and Best Practices

Beyond regulatory compliance, leading barite mining operations increasingly adopt voluntary standards and best practice frameworks:

- ISO 14001 Environmental Management System certification

- ISO 45001 Occupational Health and Safety Management System certification

- Initiative for Responsible Mining Assurance (IRMA) Standard

- International Council on Mining and Metals (ICMM) Performance Expectations

- Global Reporting Initiative (GRI) sustainability reporting framework

These voluntary commitments often exceed regulatory minimums while providing standardized approaches to management system implementation, performance measurement, and stakeholder communication increasingly important factors for market access and social license to operate.

Conclusion

Barite mining represents a vital industry supporting both energy development and various industrial applications through the extraction of this unique mineral. From exploration through processing, the industry combines geological expertise, engineering principles, and environmental management to produce materials essential for modern society.

The future of barite mining faces both challenges and opportunities. While traditional drilling markets continue to dominate demand, diversification into specialty applications offers growth potential less tied to energy sector volatility. Technological advancements across the mining value chain are enhancing efficiency and reducing environmental impacts, while sustainability considerations increasingly shape operational approaches.

As global mineral demands evolve with energy transition trends, the barite industry must navigate changing market dynamics while addressing growing expectations for environmental and social performance. Companies embracing innovation, operational excellence, and comprehensive sustainability practices position themselves for long-term success in this essential mineral sector.

The balance between meeting material needs and responsible resource stewardship remains the central challenge and opportunity for barite mining’s future. With thoughtful approaches incorporating technological innovation, environmental protection, and community engagement, the industry can continue providing essential materials while creating positive benefits for all stakeholders.

FAQs

What is barite primarily used for?

Approximately 80% of global barite production is used as a weighting agent in drilling fluids for oil and gas wells. Its high specific gravity helps control well pressure and prevent blowouts during drilling operations. Other applications include use in radiation shielding, paint and plastic fillers, friction materials, and certain medical procedures.

Where is barite most commonly mined?

The world’s largest barite producers include China, India, Morocco, the United States, and Iran, which together account for roughly 70% of global production. The Mangampet mine in India is considered the world’s largest barite deposit. Significant production also occurs in Mexico, Turkey, Kazakhstan, and Thailand.

How is barite’s quality graded?

Barite quality is primarily graded by specific gravity, with API (American Petroleum Institute) specifications requiring a minimum specific gravity of 4.2 for drilling applications. Other important quality parameters include chemical purity (BaSO₄ content), particle size distribution, and the presence of impurities such as heavy metals or silica.

Is barite mining environmentally harmful?

Like all mining activities, barite extraction creates environmental impacts that require management. These include land disturbance, potential water quality effects, and habitat modification. Modern operations implement comprehensive environmental management systems to minimize these impacts through careful planning, operational controls, and reclamation practices. The environmental footprint varies significantly based on mining method, with underground mining typically creating less surface disturbance than open-pit approaches.

What is the future outlook for barite mining?

The barite industry’s outlook remains tied to energy sector activity in the near term, creating cyclical demand patterns. Longer-term trends include growing applications in specialty markets, increasing emphasis on recovered barite from drilling waste, and higher sustainability expectations. Technological advancements in exploration, extraction, and processing continue improving efficiency and environmental performance. While facing challenges from energy transition trends, the industry’s diverse applications provide multiple pathways for continued relevance.

How is barite different from other minerals?

Barite’s most distinctive characteristic is its high specific gravity (4.3-5.0), which exceeds most non-metallic minerals. This property results from barium’s high atomic weight. Barite is also characterized by chemical stability, low solubility, and radiation-absorbing properties. Unlike many industrial minerals, high-grade barite deposits are relatively limited geographically, creating strategic importance for certain applications.

Was this comprehensive article about barite mining useful for you? We are eagerly waiting to hear your comments, questions, and experiences regarding the barite mining industry.

If you are active in the barite mining industry or interested in this field, please share your experiences with us and other readers. Your perspectives can help enrich the content and make it more valuable for the mining community